04-December-2023

The application fields of silicon nitride bearing balls are becoming more and more extensive, let us take a look.

Silicon nitride bearings are used in new energy vehicles

New energy vehicles have put forward more new requirements for automotive bearings. First of all, motor bearings have a higher speed than traditional bearings and require materials with lower density and relatively more wear resistance. At the same time, because the alternating current of the motor causes changes in the surrounding electromagnetic field, it needs to be better. The insulation reduces electrical corrosion caused by bearing discharge; third, the bearing ball surface is required to be smoother and less worn. Silicon nitride bearings are an excellent choice.

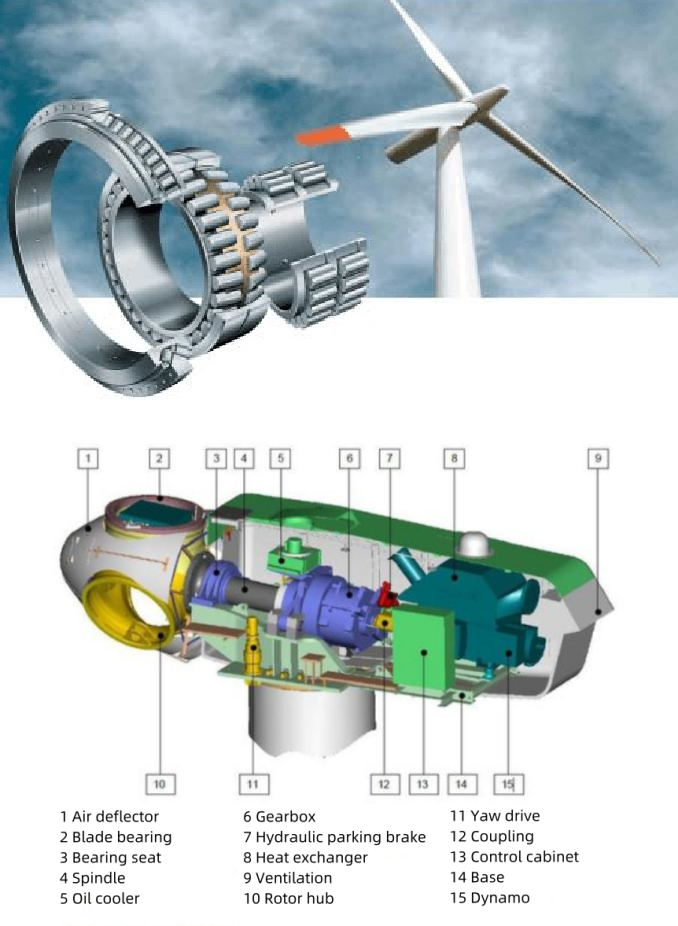

Silicon nitride bearings for wind turbines

With the increasing awareness of environmental protection and the continuous development of renewable energy, wind power has been widely used as a clean energy source. In wind turbines, silicon nitride bearing balls, as important components, play a vital role.

The silicon nitride bearing balls in wind turbines mainly play two roles: one is to support the rotation of the generator rotor to keep it balanced, and the other is to bear the huge load of the generator rotor so that it can operate stably. Moreover, the high hardness and high wear resistance of silicon nitride bearing balls can also reduce the wear and friction of the bearing balls, thereby extending the service life of the bearing balls and reducing maintenance and replacement costs.

In addition, silicon nitride bearing balls also have excellent corrosion resistance and high temperature stability, and can maintain good performance under harsh environmental conditions. In offshore wind farms, due to seawater corrosion and high temperature and high humidity environments, the service life of bearing balls will be greatly reduced, and silicon nitride bearing balls can effectively solve this problem.

The use of silicon nitride bearing balls can also reduce the noise and vibration of wind turbines and improve their operational safety and stability. In wind turbines, noise and vibration often affect the lives and work of surrounding residents. The high precision and stability of silicon nitride bearing balls can reduce the noise and vibration of the unit, making it more environmentally friendly and safer.

Silicon nitride bearing balls are used in precision bearings of machine tools

1. High hardness and high strength: Silicon nitride ceramic bearings have the characteristics of high hardness and high strength, which enable it to withstand high loads and impacts. This material performs well in the face of friction and wear, effectively extending the life of your equipment.

2. Wear resistance and high temperature resistance: Silicon nitride ceramic bearings not only have good wear resistance, but also can maintain excellent performance in high temperature environments. This makes it widely used in high-speed equipment, such as precision machine tools and aerospace engines.

3. Corrosion resistance and non-magnetism: Silicon nitride ceramics have good corrosion resistance to most chemical substances, and can effectively prevent chemical corrosion and ensure the accuracy and life of the bearing. In addition, silicon nitride ceramics have good non-magnetic properties and are suitable for applications where magnetic interference needs to be avoided.

4. Good electrical insulation properties: Silicon nitride ceramics have good insulation properties and can be used in situations where electrical insulation is required. This characteristic makes it widely used in the fields of electronics and power.

5. The linear expansion coefficient of silicon nitride is small: therefore, when the ambient temperature changes, its size change is relatively small. This characteristic makes silicon nitride bearing materials perform well in areas with large changes in ambient temperature. It can effectively prevent dimensional changes caused by temperature changes, thereby avoiding bearing locking and other phenomena.

6. Excellent self-lubricating properties: Under poor lubrication conditions, such as lean oil lubrication or oil-free dry friction, it can still show superior friction reducing and anti-wear properties.

Silicon nitride bearings arepopular in the bicycle market.

According to CeramicSpeed officials, replacing CeramicSpeed’s hub, bottom bracket and guide wheel bearings can save you about 9 watts of power compared to ordinary standard bearings. Ollie Gray, manager of The Rider Firm, said: “It may not sound like a lot, but if you ask any professional rider they will tell you that 10 watts saved could make a difference, especially in a time trial or solo breakout. In the game.”

Therefore, in the Grand Tour in recent years, professional cyclists have used a variety of ceramic bearings. The equipment matching of professional drivers has always been the object of imitation by amateurs. Naturally, amateur players are increasingly inclined to upgrade their tanks with ceramic bearings.

Silicon nitride ceramic balls for dental drill bearings

In recent years, with the improvement of people's living standards and quality of life, dental disease prevention and treatment have become increasingly important and popular. Si3N4 ceramic balls have the characteristics of high hardness (1500~2000HV), small centrifugal force, resistance to corrosion and friction and wear, and small thermal expansion coefficient (only 25% of steel balls). In addition, they absorb low heat, have low cooling requirements, and can be used in lubrication. It operates in an environment with poor conditions, so it is very suitable as a rolling element material for high-speed dental drill bearings.

Silicon nitride bearing balls for petrochemical industry

In the field of petrochemical industry, it can effectively resist the erosion of various chemical substances and improve the stability and durability of equipment.