13-October-2023

In

the past few decades, nanoscience has developed rapidly, so researchers

began to explore how to apply nanomaterial technology to enhance heat

transfer. In 1995, Choi of Argonne National Laboratory in the United

States first proposed the concept of "nanofluid", which has since

innovatively combined nanotechnology with the traditional field of

thermal engineering.

Nanofluid

is a new uniform and stable heat transfer medium prepared by adding a

certain amount of nanoparticles (size 1-100nm) to traditional liquids.

Compared with traditional heat transfer fluids, it can effectively

improve the heat transfer performance of thermal systems and meet the

enhanced heat transfer requirements under some special conditions

(microscale conditions), so it is considered a new type of heat transfer

fluid.

However,

the potential of nanofluids does not stop there. After being used in

heat exchange systems as a bridge between heat sources and cooling

equipment, it has gradually expanded to fields such as tribology, solar

collectors, and biomedicine. In the past decade, research on nanofluids

has aroused the interest of researchers at home and abroad and has

become one of the hot spots of concern.

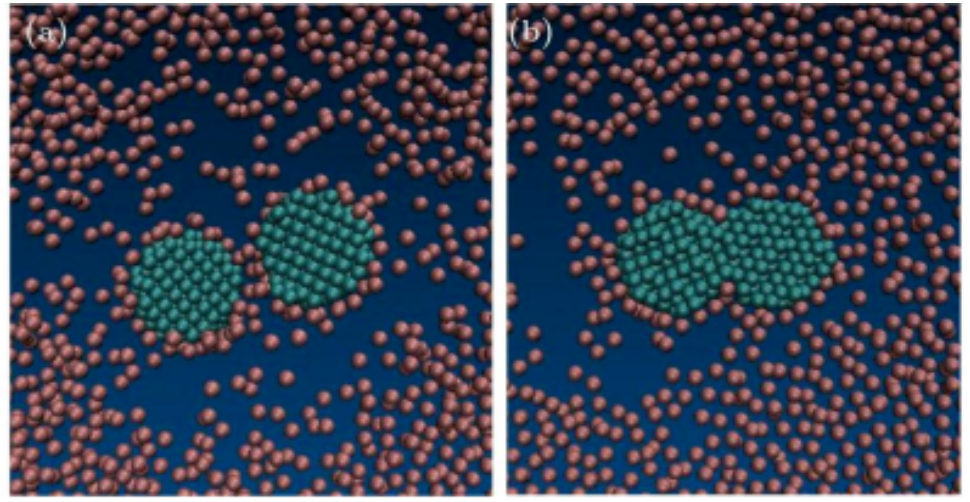

Aggregation state of nanoparticles in fluids

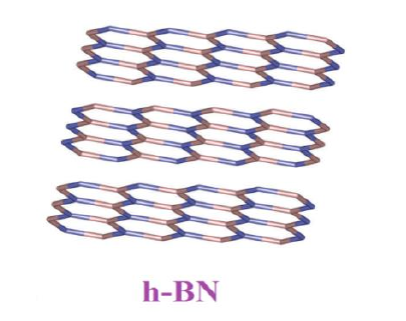

Hexagonal

boron nitride (h-BN) is an isoelectric material similar to graphite. It

has a lamellar structure similar to graphite and is called white

graphite. It has a unique structure, excellent mechanical strength, and

high thermal resistance. Stability, oxidation resistance and chemical

inertness make it a material with great application prospects. If the

h-BN sheet structure is peeled off to obtain h-BN sheets with a

thickness of several nanometers, it can become boron nitride nanosheets

(BNNS), which is another two-dimensional nanomaterial.

The most outstanding thing about boron nitride is its application advantages when used in nanofluids. details as follows:

①Improve tribological properties

Friction

exists in almost all moving systems (drilling, cutting, cutting,

machining and forming, etc.). Excessive friction will cause energy loss,

mechanical failure and low work efficiency. In order to minimize the

adverse effects of friction, solid or liquid lubricants are usually

used, with the latter generally being the first choice for eliminating

friction.

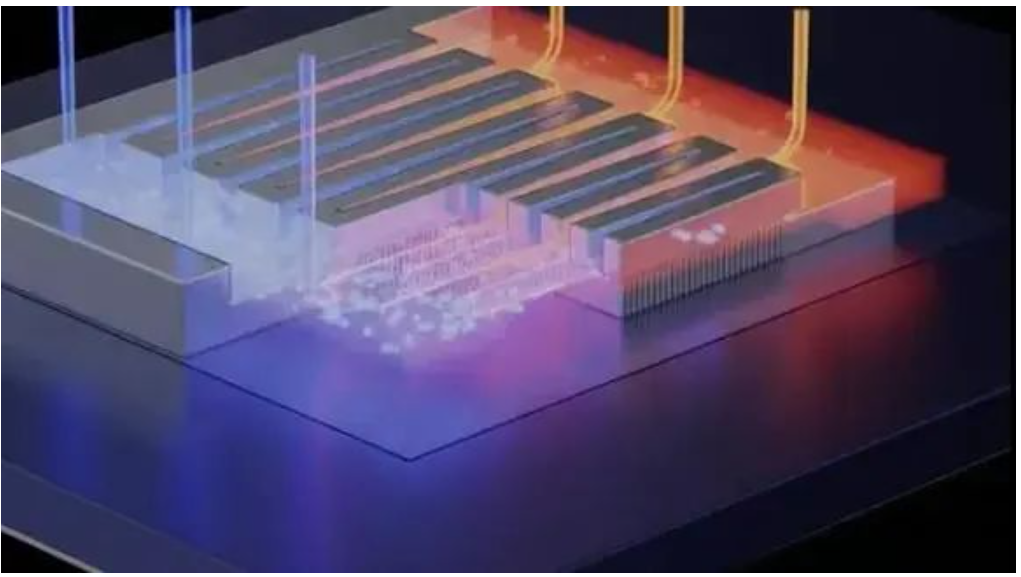

②Improve heat transfer performance

In

the electronic and electrical industry, how to improve the thermal

management capabilities of equipment is a very important topic. Many

electronic products and mechanical equipment today use air cooling to

remove waste heat. However, the thermal conductivity coefficient of air

is extremely low, which limits the heat dissipation efficiency of heat

dissipation equipment. Liquid cooling can effectively solve the heat

dissipation problem under high heat flux densities in the electrical and

electronics industry due to its high heat dissipation efficiency and

quiet operation.

③Enhance photothermal conversion efficiency

Heating

water using solar radiation is one of the many beneficial things that

can be done with solar energy. Efficient use of solar energy can reduce

or even replace the traditional way of providing the hot water needed

for equipment through the combustion of fossil fuels. The collector is a

key component of the solar water heating system, which can collect

clean solar energy and convert it into thermal energy for water heating.

Methods of increasing heat transfer through collectors can be divided

into two categories: passive methods and active methods. Compared with

active methods, passive methods do not require the action of external

force. Utilizing nanofluids as heat transfer media in direct absorption

solar collectors is a passive method to improve heat transfer.

④Improve drug loading capacity

Carbon

nanomaterials have been extensively studied in medical fields such as

biosensing, medical imaging, and cancer cell targeted therapy. However,

carbon nanomaterials have certain cytotoxicity that limits their

clinical application. Therefore, alternatives to carbon materials have

been developed. Things are very meaningful. As a structural analog of

carbon nanomaterials, BN's performance matches that of carbon materials.

Its low cytotoxicity, excellent chemical stability and high thermal

stability give it a strong competitive advantage in the medical field.

However,

it should be noted that although lower concentrations of BN have been

proven to be uniformly dispersed in water for a long time, whether

high-concentration BN materials can be effectively dispersed and stably

in different fluid media determines the performance of boron nitride

composite nanofluids. The key to large-scale application is that more

research on new processes is needed in this regard.