23-October-2023

With the rapid development of modern electronic products towards miniaturization, multi-function and high performance, overheating will reduce the performance, life and reliability of electronic and electrical equipment. How to dissipate heat efficiently has become an urgent issue. Polymers have been widely used as electronic packaging materials for electrical devices due to their high electrical insulation properties, light weight, and ease of processing, not only reducing the size and weight of components but also simplifying assembly. However, most polymers themselves are poor conductors of heat (thermal conductivity is between 0.1~0.5W/mK) [for example, the thermal conductivity of polytetrafluoroethylene, the resin used in high-frequency copper clad laminates, is about 0.20~0.24W/(m.K )], the introduction of high thermal conductive fillers to prepare polymer-based composite materials is currently a widely recognized feasible method to improve the overall thermal conductivity of materials. Common thermal conductive fillers include metals, metal oxides and nitrides, and carbon-based thermal conductive fillers.

Although metal particles and carbon-based materials have high intrinsic thermal conductivity and are widely used, such fillers not only change the thermal conductivity but also change the electrical insulation properties of the polymer, such as leading to extremely high electrical conductivity of the polymer. , high dielectric constant, so this type of material is not suitable for occasions that require high insulation performance. Therefore, the insulation field is paying more attention to inorganic particles with extremely high intrinsic thermal conductivity and good insulation properties. At present, inorganic particles including aluminum oxide, magnesium oxide, aluminum nitride, boron nitride and other inorganic particles have been widely used in high thermal conductivity polymer-based composite materials.

Usually, the crystal structure of hexagonal boron nitride (h-BN) is the same layered structure as graphite, and its particle shape is scaly (related reading: White graphite hexagonal boron nitride has a similar structure to graphite, why h-BN is not conduct electricity?), has excellent thermal conductivity (in-plane thermal conductivity experimental value 220–420W/mK, theoretical value up to 550W/mK), has excellent electrical properties and insulation, and is considered to be the most ideal insulating thermal conductivity so far filler.

Electrical characteristics

Low dielectric constant: approximately 4.0 over a wide frequency range

Low dielectric loss tangent: 3×10–4

Insulation

Band gap width: 5.2-5.8eV

Advantages of spherical boron nitride agglomerated particles: high filling and isotropy

However, if we want to obtain polymer-based thermal conductive materials with high thermal conductivity, it is not enough to just look at the intrinsic thermal conductivity of the filler. We also need to pay attention to its process. In the preparation process of polymer matrix composite materials, adding a very small amount of flaky boron nitride will cause the viscosity of the system to increase sharply. It is very difficult to add a volume content higher than 20%, and spherical boron nitride Agglomerated particles can reduce the impact of filler addition on the viscosity of the polymer composite system.

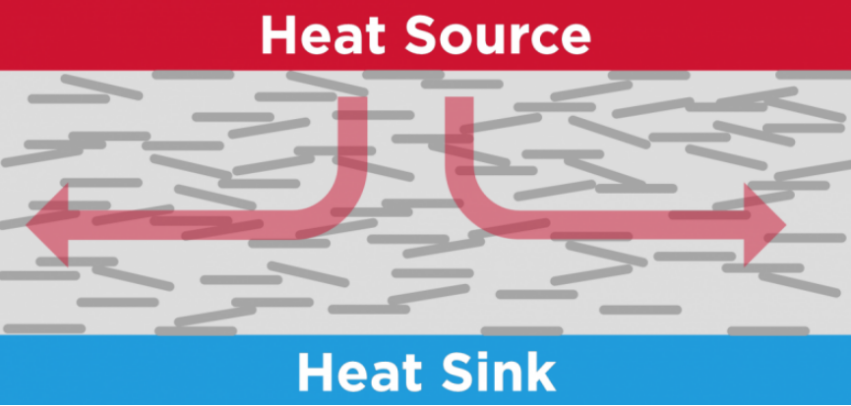

In addition, scaly hexagonal boron nitride has anisotropic thermal conductivity characteristics, with high thermal conductivity in the in-plane direction (220–420W/mK), but low thermal conductivity in the thickness direction (2-40W/mK). In addition, If scaly particles are filled into resin to form a sheet, the h-BN particles in the filled resin tend to orient in the plane direction of the sheet, and the thermal conductivity in the thickness direction of the resin sheet cannot be effectively improved.

Schematic diagram of heat conduction direction (reference source: Saint-Gobain)

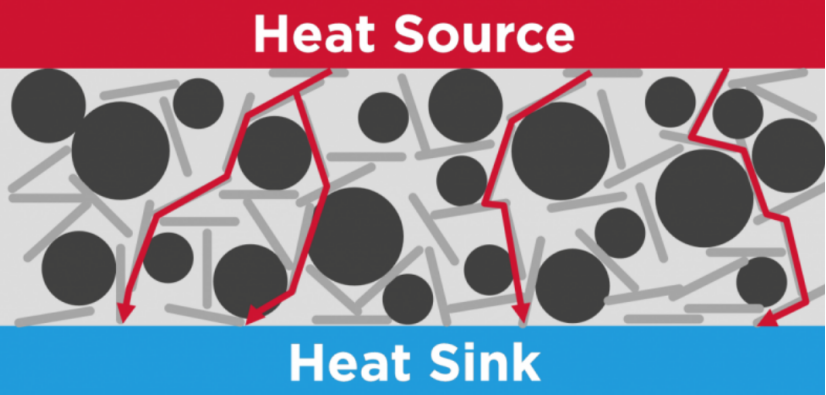

In order to improve the thermal conductivity anisotropy of scaly BN particles, h-BN particles are granulated by spray drying or the like (spherical boron nitride agglomerated particles can be produced), h-BN is sintered, and the sintered body is pulverized. BN particles and other methods are used to keep the scaly BN particles randomly oriented, so that the material has isotropic thermal conductivity.

Of course, although spherical boron nitride is very good at improving the thermal conductivity of polymers, the actual application is to "mix and match multiple fillers" to more significantly improve the thermal conductivity and heat dissipation capabilities of polymers, such as alumina with spherical boron nitride, flake Boron nitride is matched with spherical boron nitride, large particle spherical boron nitride is matched with small particle spherical boron nitride~

Combination of flaky and spherical boron nitride particles significantly improves polymer thermal conductivity