01-November-2023

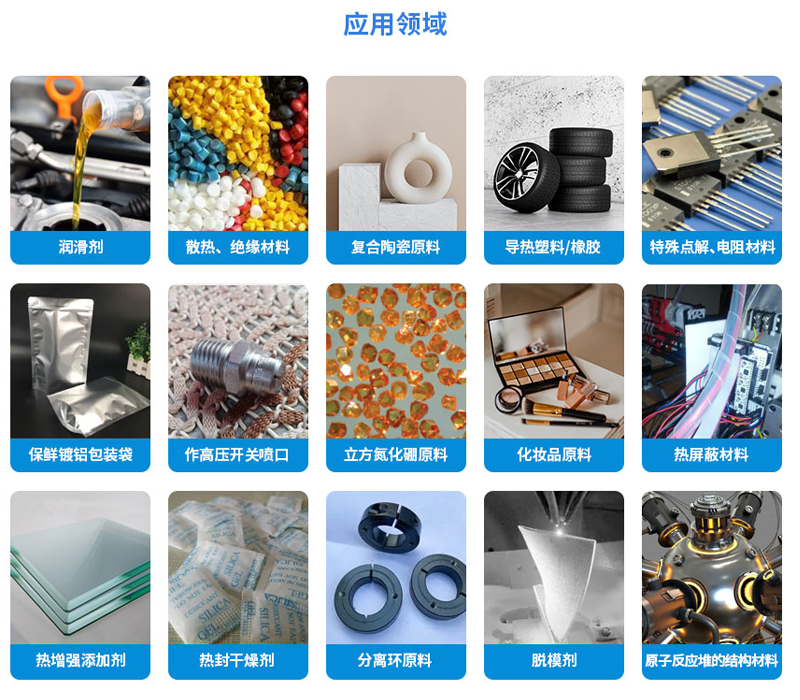

Hexagonal boron nitride (h-BN) has a series of excellent properties. As a major structural ceramic material, it has been successfully used in many fields. With the extensive development of research, the functional properties of h-BN have been gradually developed, and it has broad application prospects in new energy, electronics and other fields. In addition, h-BN is also an ideal candidate material for certain harsh service environments with structural and functional integration requirements.

h-BN has good high-temperature stability, has no obvious melting point under standard atmospheric pressure, and sublimes above 3000°C. The heat-resistant temperature of h-BN can reach 2800°C in nitrogen or argon without softening, and the heat-resistant temperature can also reach 2000°C in a neutral reducing atmosphere; however, it is prone to oxidation in an oxygen atmosphere to form oxidation with a low melting point. Boron results in poor stability, and the use temperature is generally below 900°C.

h-BN has excellent thermal conductivity. The room temperature thermal conductivity of hot-pressed dense bulk ceramics can reach more than 50W/(m·K), second only to beryllium oxide and aluminum nitride among ceramic materials, and has the same thermal conductivity as steel. The conductivity is close. It is worth pointing out that the thermal conductivity of h-BN ceramics has a slight downward trend with temperature increase. Above 600°C, its thermal conductivity is higher than that of BeO. At 1000°C, the thermal conductivity in the direction perpendicular to the c-axis arrangement is It is about 27W/(m·K) higher than most electrical insulators (thermally sintered h-BN has texture characteristics, resulting in differences in performance in different directions). If the density of h-BN-based composite ceramics is increased by adding sintering aids, modification equalizers, etc., its thermal conductivity is expected to be further improved.

The thermal expansion coefficient of h-BN ceramics is also relatively low. For bulk ceramics with no obvious texture after sintering, the thermal expansion coefficient is (2.5~4)10-6K-1. However, for textured h-BN ceramics with obvious preferred grain orientation, the thermal expansion coefficient along the direction perpendicular to the c-axis arrangement is generally less than 1x10-6K-1, while the thermal expansion coefficient parallel to the c-axis arrangement direction increases significantly. It can reach more than 10X10-6K-1, and the difference between the two can be more than 10 times.

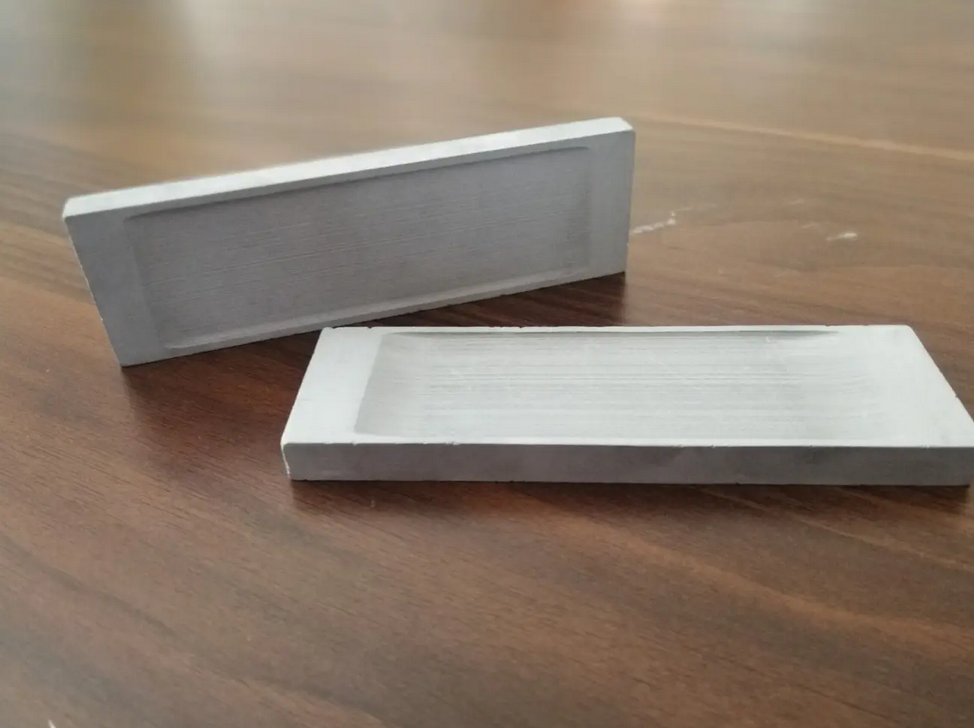

Based on high thermal conductivity, low thermal expansion coefficient and elastic modulus, h-BN ceramics have excellent thermal shock resistance, and the material can remain undamaged after repeated strong thermal shocks. Hot-pressed h-BN ceramics; after the sample is incubated in a high temperature environment of 1000°C for 20 minutes, it is immediately moved to the air to cool or cooled to room temperature with a fan, and then returned to the high temperature environment. This cycle can be repeated hundreds of times to keep the material from deteriorating. Cracked and damaged, but the strength is slightly reduced.

h-BN is a good room temperature and high temperature electrical insulator. In a dry environment, the resistivity of high-purity h-BN ceramics can reach 1016~1018cm. Even at 1000℃, the resistivity can still remain at 1016~1018cm. However, as the humidity increases, the resistivity of h-BN will decrease. ;h-BN has a very high breakdown voltage, up to 30~40kV/mm, so it is an ideal candidate material for high-frequency insulation, high insulation, and high-temperature insulation; the dielectric constant e value of h-BN is 3~ 5. The dielectric loss is (2~8)10-4, which is also relatively small among ceramic materials.

h-BN has excellent chemical stability, is insoluble in cold water, hydrolyzes very slowly in boiling water and produces small amounts of boric acid and ammonia. h-BN has considerable corrosion resistance to various inorganic acids, alkalis, salt solutions and organic agents. It has excellent stability in most acids and alkali and is inert to weak acids and strong alkali at room temperature. Reaction, the mass loss rate of samples soaked in concentrated sulfuric acid, nitric acid, phosphoric acid and other solutions for 7 days was less than 10%, slightly helped by hot acid, and after treatment with molten sodium hydroxide (NaOH), potassium oxide (KOH), etc. can decomposition occur. In addition, h-BN neither wets nor reacts with high-temperature melts of most metals and glasses, so it can be used as an ideal stacking material for melting various metals.

h-BN has high thermal stability and low dielectric loss, making it one of the materials suitable for manufacturing high-temperature radomes/windows. Although it has problems such as low hardness and poor rain corrosion resistance, h-BN ceramics can be composited with silicon nitride, silicon oxide, etc., which can not only improve the sintering characteristics, but also have the advantages of each component, and can meet the needs of Under high Mach number flight conditions, radome/window components have various complex performance requirements such as heat protection, load-bearing, and wave transmission.

For Hall electric thrusters that can be used for attitude control, orbit insertion, transfer, and maintenance of satellites and deep space probes, the key component nozzle material is required to have good heat resistance, cycle thermal shock resistance, and high-temperature electrical insulation. , resistance to ion sputtering erosion, and suitable secondary electron emission coefficient, h-BN ceramic is the most suitable material for preparing nozzle components.

h-BN and its composite ceramics have been widely used as high-temperature refractory materials, such as TiB-AIN-BN composite ceramic evaporation boats, SigN-BN separation rings, special metal high-temperature electrolytic cells, high-temperature collapses, casting shells, etc. . With the deepening of research and the expansion of application requirements, the performance of this series of ceramic materials has been greatly improved, and the application fields have also been broadened.

h-BN has the characteristics of high insulation and high thermal conductivity, and can be used as a heat dissipation management device in electronic circuits. When single-layer or few-layer h-BN nanomaterials prepared by chemical vapor deposition or liquid phase exfoliation are applied to the chip surface, they can not only play a protective role, but also take advantage of the excellent lateral transmission brought by its special two-dimensional structure. Thermal capability can quickly spread the heat of local hot spots of high-power electronic devices laterally, reducing the local maximum temperature, thus improving the life and reliability of the device. In addition, h-BN powder is also an ideal polymer filler. Adding it to resin, rubber, plastic and other materials can increase thermal conductivity and improve insulation properties, which is important for the use of polymer materials in flexible electronic devices. Applications play an important role.

h-BN also has a wide range of applications in other fields:

● Boron-containing compounds have certain properties against neutron radiation, and h-BN can also be used in packaging materials to prevent neutron radiation, structural components of atomic reactors, etc.;

● h-BN’s high temperature resistance, chemical stability and good high temperature lubrication properties make it suitable for use as high temperature lubricants or release agents for molds, anti-sticking agents for melts, etc.;

● High-purity h-BN has good adhesion, soft and smooth texture, and has a lower friction coefficient than traditional cosmetic powders (such as talc powder, mica, etc.). It can be used as high-end cosmetics such as powder cakes, lipsticks, lip glosses, skin care products, etc. Product fillers;

● Recent studies have shown that various forms of h-BN can initiate or catalyze a series of reactions through the formation of some free radicals, including acetylene chlorination and propane dehydrogenation. Therefore, it can be used as a catalyst carrier and can also pass through Doping, modification and other means can be directly used in catalytic reactions, showing good application potential.