06-March-2024

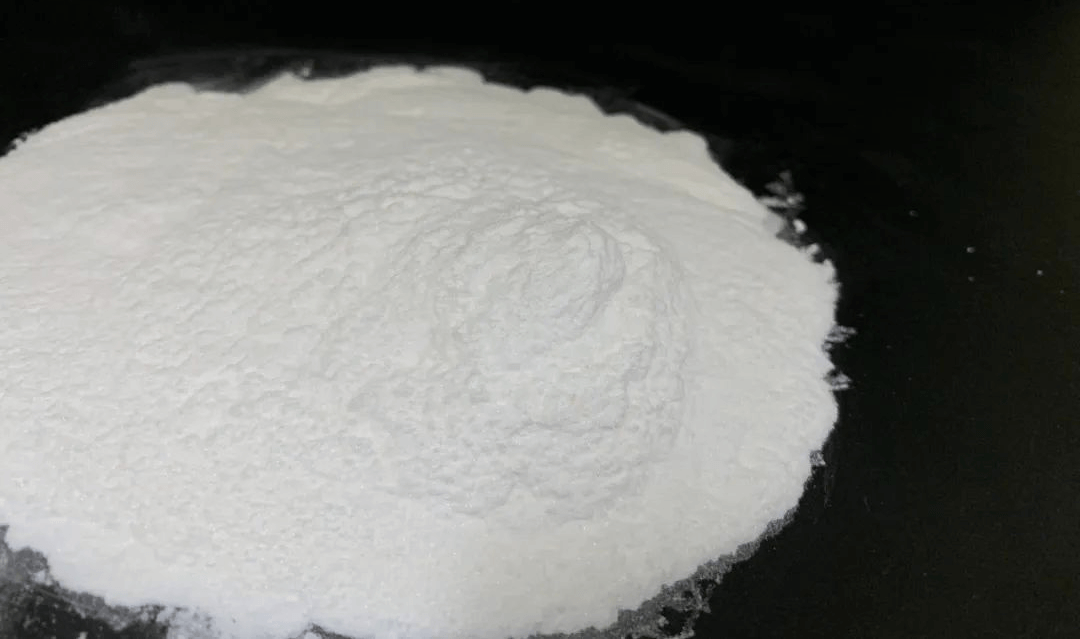

Hexagonal boron nitride (h-BN) is an excellent high-temperature lubricant with extremely low friction coefficient, stable performance in high-temperature environments, and does not increase as the temperature increases. This characteristic gives it unique advantages in the field of high-temperature lubrication, so it has been widely used in various high-temperature lubrication situations in recent years.

In terms of mechanical applications, hexagonal boron nitride, with its unique crystal structure, can be made into a solid lubricant and directly coated on the surface of mechanical parts to reduce friction between mechanical parts; it can also be added to liquid lubricants to form lubrication. Film, this application method enables it to maintain good lubrication performance in high temperature environments, and has significant advantages in extending the life of mechanical components and reducing energy consumption. In addition, when hexagonal boron nitride is used as a solid lubricant, it can be dispersed in heat-resistant lubricating grease, water or solvent, and adhered to the friction surface by spraying. After the solvent evaporates, a dry film is formed to Lubricating effect.

During the forging process of special alloys, the blank body will be coated with a layer of glass-based antioxidant to achieve the effect of reducing oxidation of the blank during the heating process and serve as a lubricant during the forging process. However, usually these glass-based antioxidants The lubrication effect is not ideal, so the industry will spray a layer of graphite on the mold to enhance the lubrication effect during forging. Among them, since the solvents used in the coating and removal process of glass-based antioxidants will cause environmental pollution, such a process cannot achieve the goal of green production. Water-soluble hexagonal boron nitride is used to replace glass-based antioxidants and graphite. Since the price of the glass-based antioxidant itself is also very high, switching to hexagonal boron nitride will not increase the production cost, but it can significantly improve the working environment of the forging plant and bring the forging industry into the green production industry. among the ranks. Research on the friction properties and electrical properties of hexagonal boron nitride can be used as a release agent for metal molding, an insulator for high-voltage and high-frequency electric and plasma arcs, a release agent for optical glass, and an evaporation boat for various aluminum plating. In metallurgy, it is used as a separation ring for continuous steel casting, a lubricant for metal wire drawing, etc. It can be seen that in-depth research on hexagonal boron nitride nanomaterials in biology, aerospace, energy, electronics and other related fields has very important scientific value and socio-economic significance.