25-March-2024

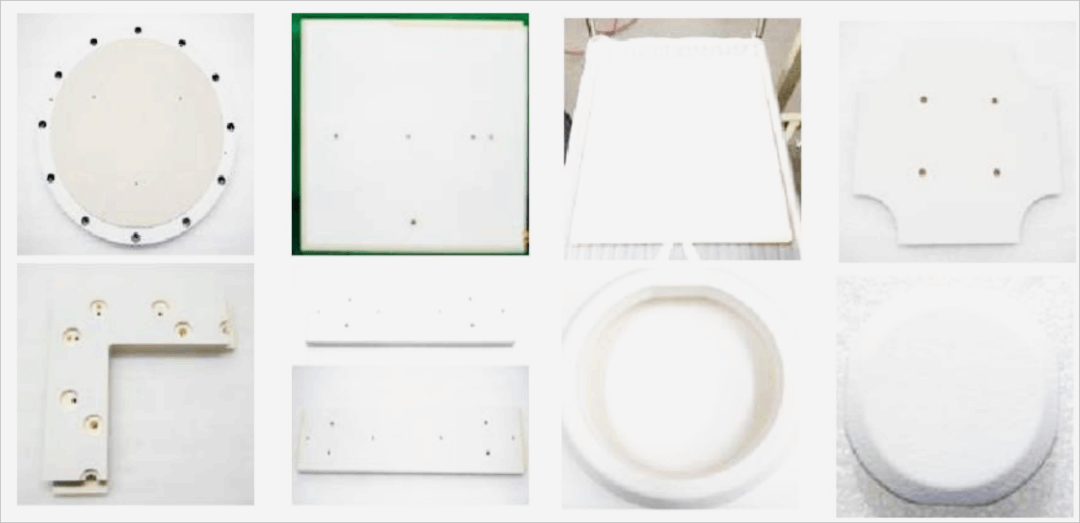

Yttrium oxide spray etching cavity and mold components

The advantages of Y2O3 as an etching-resistant material are as follows:

(1) Due to the elimination of AlF3, surface particle and defect contamination caused by Y2O3 is reduced.

(2) The transition metal content in the material is low, which reduces the risk of metal contamination.

(3) Y2O3 has better dielectric properties, and the thicker the Y2O3 ceramic coating, the stronger its ability to resist dielectric breakdown.

(4) As a plasma cavity-resistant material, the corrosion rate in plasma is low.

At present, the main application scenarios of yttrium oxide ceramics in etching machines are chambers and window mirrors.

In the cavity, in addition to making the entire cavity, considering the price factor, Y2O3 coating is often sprayed on other ceramic substrates to achieve the purpose.

The window mirror material on the etching machine requires high light transmittance. Quartz glass material was initially used, but it was easily corroded and blurred, and was later replaced by Al2O3 material. However, with the application of fluorine-containing plasma, the corrosion resistance of Al2O3 gradually cannot meet the needs of mass production, because the Al in Al2O3 reacts with fluorine ions to generate Al–F compounds, which then deposit and crystallize to form particulate impurities, which can easily contaminate the crystal. round. Y2O3 transparent ceramics have received great attention for exhibiting very good corrosion resistance in fluorine-containing plasma.

Although Y2O3 ceramics have excellent plasma etching resistance, its practicality is limited due to poor compaction and sintering capabilities, low mechanical strength, and difficulty in processing. In addition, as a rare earth material, Y2O3 is difficult to sinter and expensive. Simply using Y2O3 to prepare corrosion-resistant devices in semiconductor production has high production costs. Therefore, yttrium oxide is sometimes subject to certain limitations as an etching-resistant material.

Some scientific researchers have discovered through research on Y2O3 ceramics that when a certain amount of alumina is added, a new yttrium oxide-based composite material, namely yttrium aluminum garnet, will be formed. Compared with pure Y2O3 ceramics, yttrium oxide-based composite ceramics have the characteristics of good plasma corrosion resistance, higher mechanical properties, and low manufacturing cost.

In addition, in addition to compounding with alumina, yttria-stabilized zirconia ceramics have also become a major research direction in etching-resistant materials.

Product page:https://www.ceramic-solutions.com/Boron-Nitride.html

Contact page:https://www.ceramic-solutions.com/Contact.html