Cersol’s aluminum nitride (AlN) crucibles specifically designed to meet the demanding requirements of high-temperature processes. Unlike traditional ceramic materials, AlN offers a unique combination of exceptional Thermal conductivity, Insulation conductivity, High temperature stability and Mechanical properties. This makes our crucibles an ideal solution for applications where a conventional material like alumina or graphite would fail.

Cersol AIN Crucible

1. The core advantages of Cersol AIN Crucibles

Strong Processing Capabilities:Cersol has excellent capabilities in processing aluminum nitride and has a lot of experience in processing aluminum nitride crucibles.Cersol can process aluminum nitride into complex and difficult aluminum nitride crucibles.

High Purity:Aluminum nitride has a high purity, with levels often reaching 99.9%, which is essential for its use in advanced high-tech applications.

High Thermal Conductivity: AlN has a thermal conductivity (170-200 W/m·K) that is superior to other technical ceramics, allowing for rapid and uniform heat distribution.

Excellent Electrical Insulation: Despite being a great thermal conductor, AlN is a powerful electrical insulator. This unique combination makes it highly valuable in the semiconductor industry for manufacturing and processing electronic components.

High-Temperature Stability and Thermal Shock Resistance: AlN crucibles can withstand temperatures up to 2100°C in inert atmospheres. Their resistance to thermal shock (the rapid change in temperature) prevents cracking and ensures a longer service life, making them reliable in extreme conditions.

Superior Chemical Inertness: They are non-reactive and non-wetting with most molten metals, including aluminum, gallium, and copper. This prevents contamination of the molten material.

2. Introduction of aluminum nitride crucible raw materials

The primary raw material for aluminum nitride (AlN) crucibles is high-purity aluminum nitride powder. This powder is synthesized from aluminum and nitrogen.

Purity: The purity of the AlN powder is paramount. Trace impurities, particularly oxygen and carbon, can significantly degrade the thermal and electrical properties of the final crucible.

Particle Size and Distribution: The powder consists of very fine particles, often with a mean diameter around 1-10 micrometers.Its uniform and narrow particle size distribution enables high-density and defect-free structures during sintering.

Crystalline Structure: AlN powder has a wurtzite crystal structure, which is a hexagonal lattice. This specific structure is what gives AlN its inherent high thermal conductivity and excellent electrical insulation.

Stability: The powder is stable in an inert atmosphere, but it is susceptible to hydrolysis (reaction with water) in moist air.

3. Manufacturing process of aluminum nitride crucible

The manufacturing of an aluminum nitride (AlN) crucible typically involves a multi-step process that transforms high-purity AlN powder into a dense, durable ceramic product. The main steps are powder preparation, forming, and high-temperature sintering.

Powder Preparation: High-purity AlN powder, often with sintering aids like yttrium oxide (Y2O3), is mixed with organic binders and plasticizers to form a homogeneous slurry or paste.

Forming: The prepared mixture is shaped into the desired crucible form using techniques such as slip casting, isostatic pressing, or injection molding. This process creates a "green body," which is a fragile, unsintered form of the crucible that holds its shape.

Drying: The green body is carefully dried in a controlled environment to remove the binder and any remaining moisture.

Sintering: The dried green body is fired in a high-temperature furnace (typically above 1800℃) under a nitrogen atmosphere. During this process, the AlN particles bond together, densifying the material and give the crucible excellent strength and high thermal conductivity.

Machining and Finishing: After sintering, crucibles are precision machined using diamond tools to achieve final dimensions and surface finish.

|

Item |

Units |

CN-230 |

CN-210 |

CN-180 |

CN-170I |

CN-170H |

CN-999 |

|

|

Density |

—— |

g/cm3 |

3.33 |

3.33 |

3.32 |

3.32 |

3.34 |

3.25 |

|

Thermal conductivity |

25℃ |

W/m·K |

230 |

210 |

180 |

170 |

170 |

100 |

|

Bending strength method |

3-point method 25℃ |

MPa |

200 |

300 |

410 |

410 |

550 |

450 |

|

Insulation |

25℃ |

KV/mm |

25 |

27 |

31 |

31 |

19.2 |

18.8 |

|

Volume resistity |

25℃ |

Ω·m |

2.8x1013 |

6.5x1013 |

3.4x1014 |

4.96x1014 |

8.6x1014 |

3.6x1014 |

|

Dielectric constant |

1MHz |

—— |

8.9 |

8.9 |

8.8 |

8.8 |

8.8 |

8.8 |

|

Dielectric loss |

1MHz |

—— |

4.6x10-4 |

5.0x10-4 |

6.5x10-4 |

6.6x10-4 |

2.8x10-4 |

2.7x10-4 |

|

CTE |

25~400℃ |

10-6/K |

4.9 |

4.9 |

4.6 |

4.6 |

4.6 |

4.8 |

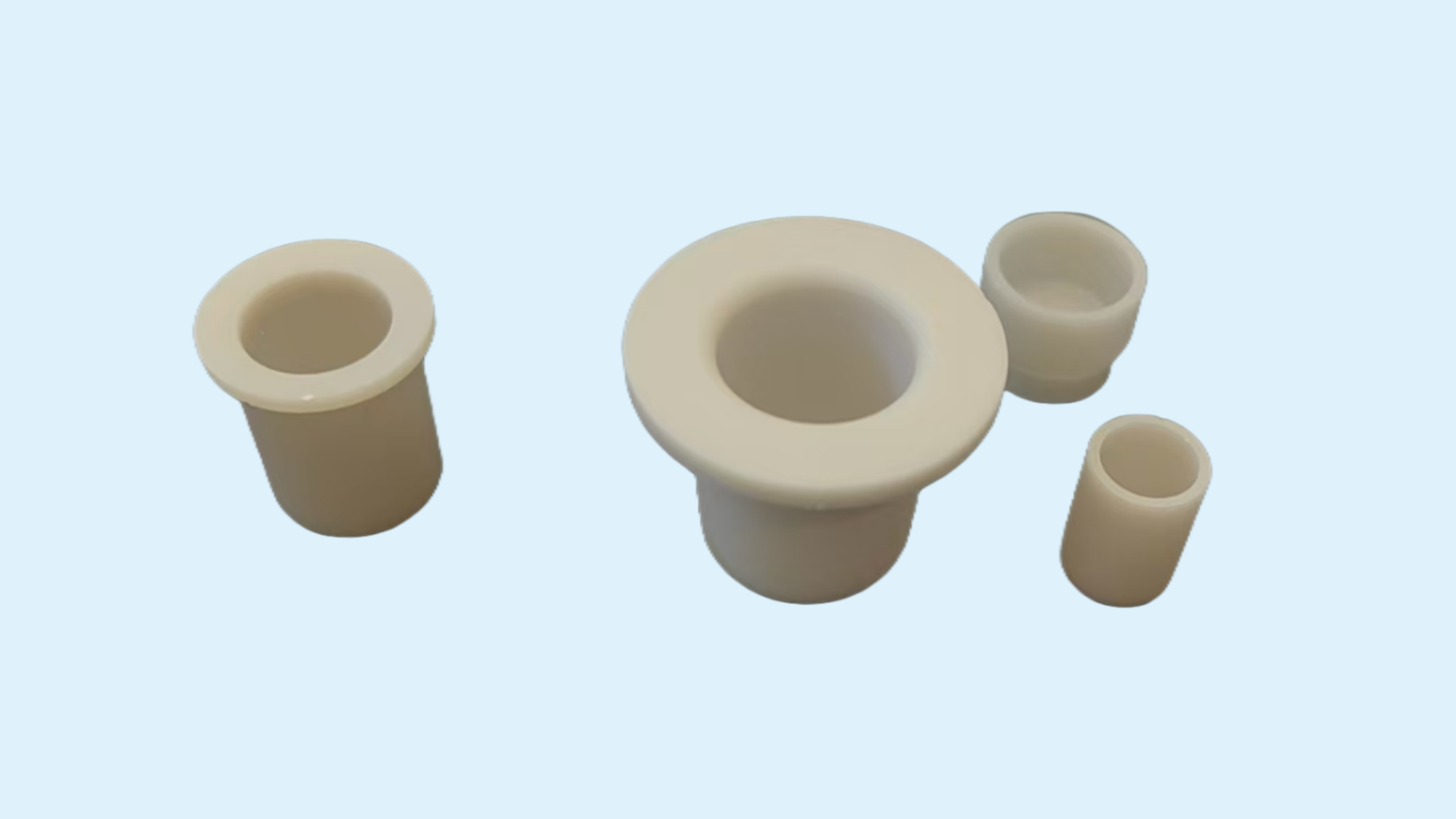

4. Classification of aluminum nitride crucibles

Aluminum nitride crucibles are not typically categorized by their shape and size, which are customized for specific applications.

Cylindrical Crucibles: These are used when uniform heating is required, especially in processes like crystal growth. Their simple, rounded design ensures even heat distribution to the material inside.

Conical Crucibles: Featuring a tapered design, these crucibles make pouring and retrieving molten materials easier, making them useful in metal evaporation processes where precise material transfer is crucial.

Rectangular Crucibles: These provide a flat, uniform surface for spreading materials and are ideal for solid-state reactions or chemical processes that require consistent heating across a broad area.

Custom shapes: Cersol's strong processing capabilities and rich production processes allow us to customize special-shaped AlN ceramics according to your needs, including but not limited to vase-shaped crucibles, crucibles with leaky spouts, etc.

Click here to share your needs!

5. Application of aluminum nitride crucible

High-Purity Metal Melting: They are employed for melting and purifying rare earth metals and other high-purity metals where contamination must be minimized.

Crystal Growth Furnaces: Used as containers in specialized furnaces for growing various types of crystals, including optical and laser crystals, requiring precise thermal control and inert environments.

Evaporation Sources: In thin-film deposition techniques, AlN crucibles serve as evaporation sources for metals and alloys, ensuring high purity and controlled deposition rates.

Click here to contact us!