Exceptional High-Temperature Stability

With a melting point of 2852°C, Magnesium Oxide allows these crucibles to maintain excellent structural integrity at operating temperatures exceeding 2000°C. It is one of the highest temperature-resistant materials among commercially available ceramics, far surpassing Alumina or Zirconia.

Superior Resistance to Alkaline Corrosion

MgO is a classic alkaline refractory material. When melting strong alkaline substances, basic slags, or alkali metals (such as Uranium, Lithium, and Sodium), MgO crucibles exhibit high chemical inertness, effectively preventing chemical reactions between the melt and the crucible wall.

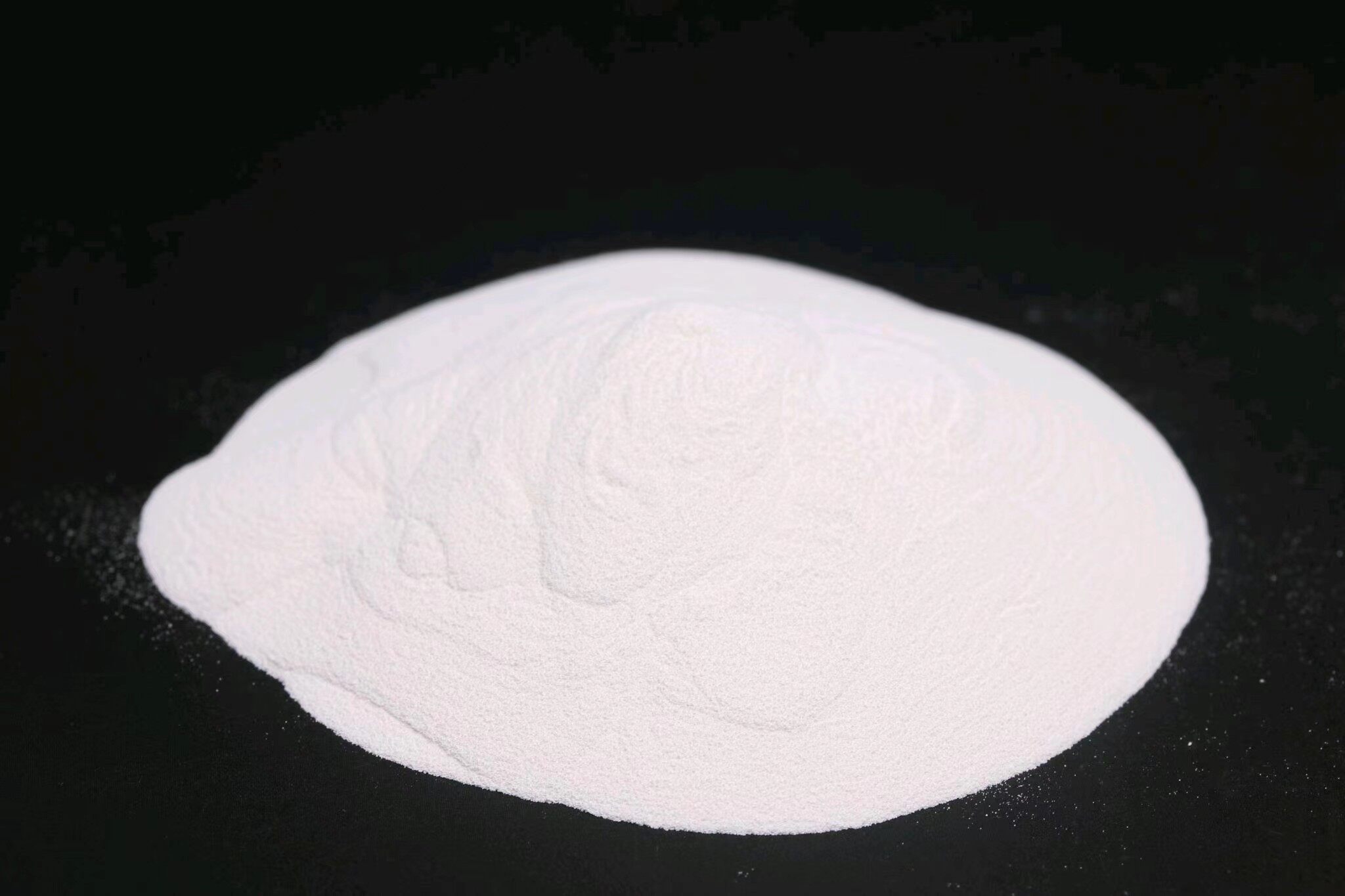

High Purity, Low Contamination Risk

We utilize industrial-grade MgO raw materials with purity levels ranging from 99.0% to 99.7%. The extremely low impurity content ensures that no foreign contaminants are introduced when melting high-sensitivity materials like superconductors or precious metals, guaranteeing the purity of your results.

Excellent Thermal Conductivity and Thermal Shock Resistance

MgO possesses high thermal conductivity, enabling rapid and uniform heat transfer. Through optimized microstructure design, our crucibles demonstrate excellent thermal stability during rapid heating and cooling cycles, significantly reducing the risk of cracking.