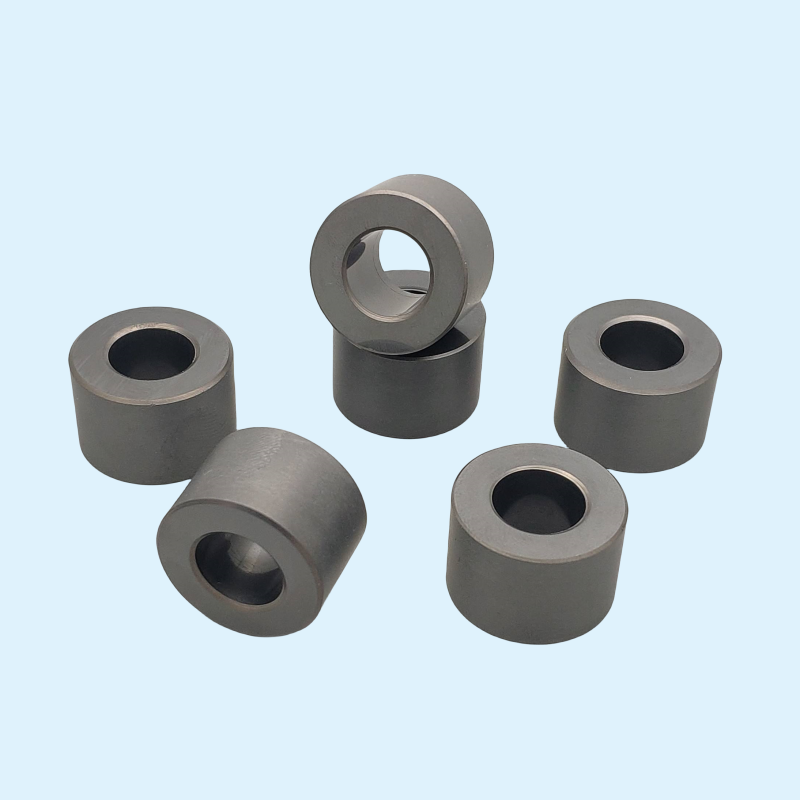

The advantages of Cersol's silicon nitride (Si3N4) grinding rings are primarily due to their superior material properties, which allow them to outperform traditional grinding media like steel and zirconia in demanding environments.

|

Product specification: |

||

|

Item |

Index |

|

|

Outside diameter |

38mm |

|

|

Inside diameter |

20mm |

|

|

Height |

25mm |

|

|

Technical Parameters: |

||

|

Bulk density |

3.2g/cm3 |

GB/T 25995 |

|

Flexural strength |

600-1000MPa |

GB/T 6569 |

|

Vickers Hardness |

≥1580 kgf/mm2 |

GB/T 16534 |

The unique properties of silicon nitride grinding rings make them a preferred choice for a variety of specialized applications where purity, efficiency, and longevity are paramount.