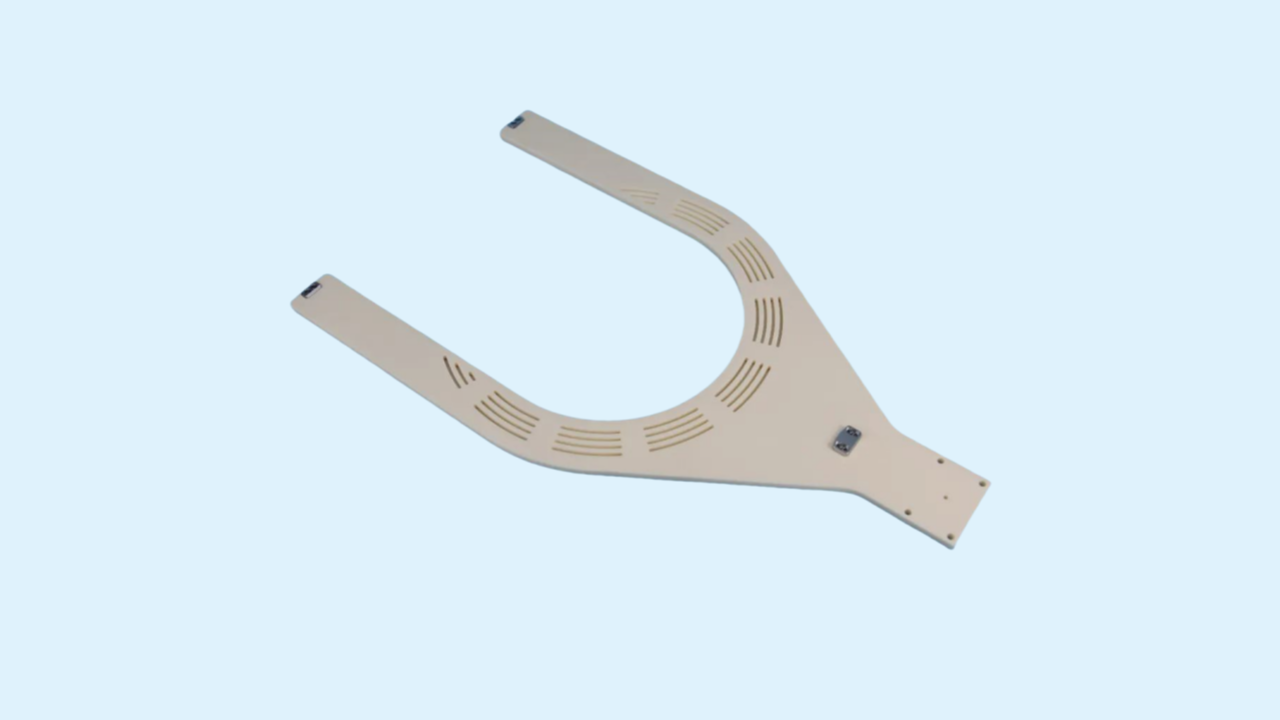

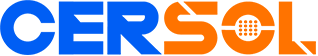

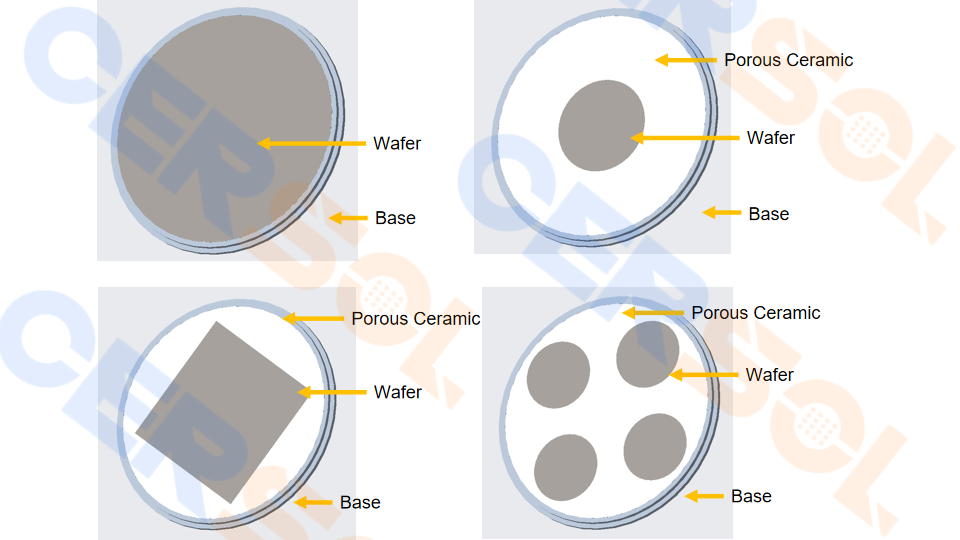

Partial Adsorption / No Leakage

Ensures stable vacuum pressure even when the wafer only covers a portion of the chuck surface. Ideal for handling multiple small parts simultaneously without the need for zone control.

High Flatness & Support

The micro-porous structure provides uniform support across the entire surface, preventing thin wafer deformation (dimples) commonly caused by traditional hole-based chucks.

Wear Resistance & Cleanliness

Highly durable ceramic material reduces particle contamination and resists chemical corrosion, making it perfect for cleanroom environments.

Customizable Pore Sizes

Available in various pore sizes (2μm to 100μm) to balance suction force and surface smoothness for specific process requirements.