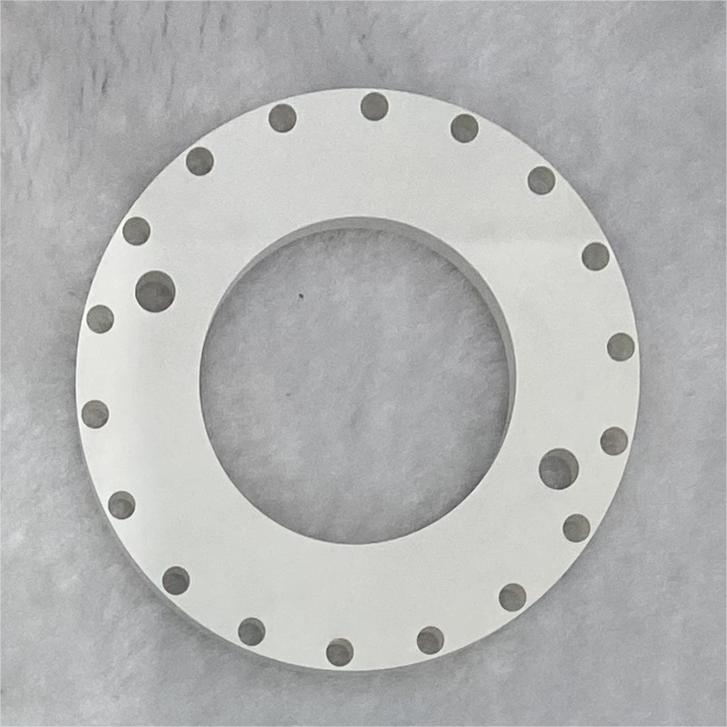

Product Name: Boron Nitride Insulation Ceramics Parts

Features: good heat resistance, thermal stability, thermal conductivity etc.

Size and shape can be cuatomized by your drawings.

Applications: semiconductor heat dissipation and insulation parts.

Hexagonal boron nitride ceramic products

Product Advantages:

Boron nitride ceramic parts have good heat resistance, thermal stability, thermal conductivity and high-temperature dielectric strength, making them ideal applications for heat dissipation and high-temperature insulation environments.

Boron nitride ceramics have good chemical stability, can resist the erosion of most molten metals, and have excellent self-lubricating properties.

Applications:

Hexagonal boron nitride ceramics can withstand high temperatures in high vacuum environments and have excellent corrosion resistance and corrosion resistance. Therefore, BN ceramic products are ideal for many industries such as:

Product Performance:

General technical parameters:

| Items | High purity boron nitride ceramics | |

| Main ingredients | BN | 99.60% |

| Density | g/cm³ | >2.0 |

| O(%) |

|

0.47% |

| Porosity |

|

2.60% |

| Leeb hardness | HL | >300 |

| Three-point bending strength | Mpa | 35 |

|

Thermal expansion coefficient (25℃-1200℃) |

(10 -° /K) | -3.5 |

| Thermal conductivity (25℃) | W/mk | 50 |

| Maximum operating temperature | in air | 900℃ |

| in vacuum | 2100℃ | |

| in inert atmosphere | 2300℃ | |

| Room temperature resistivity | Ω.cm | >1014 |

Customized Product: