14-March-2024

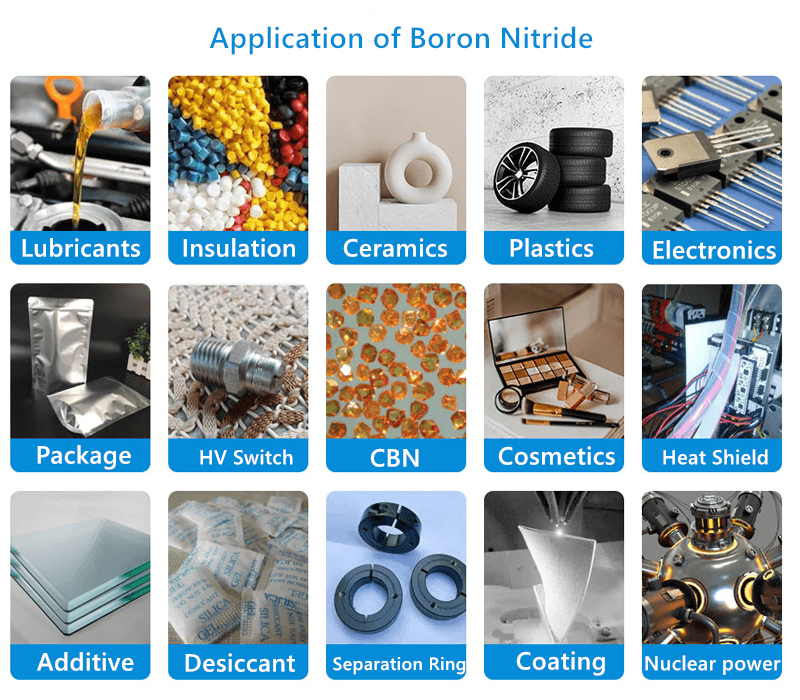

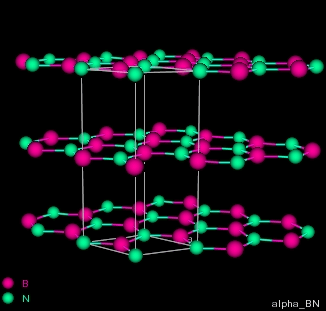

Hexagonal boron nitride (h-BN), also known as "white graphene", is a layered crystal with a graphene-like structure. h-BN has good thermal and electrical properties, excellent high temperature resistance and corrosion resistance, good mechanical properties and chemical properties. It is also an excellent insulator at high temperatures and has good machining performance. It has great development potential. It has important applications in thermal conductivity, metallurgy, lubrication, insulation, hydrogen storage, electronics industry, high-temperature anti-oxidation coating, aerospace and other fields.

Thermal conductive filler material

h-BN also has ultra-high thermal conductivity, among which the theoretically calculated thermal conductivity of hexagonal boron nitride nanosheets (BNNS) is as high as 1700~2000W·m-1·K-1. More importantly, h-BN has excellent insulation properties, with a bandgap width of 5.2eV and a breakdown strength of up to 35kV/mm, which allows h-BN to be used in conditions that require both insulation and heat dissipation. This is something that graphene cannot match. Precisely because of the above-mentioned excellent properties, h-BN is a thermally conductive filler with great application value and prospect.

Especially with the development of science and technology, electronic products are becoming more and more compact and integrated. The improvement of performance will inevitably lead to problems in heat dissipation, which will affect the working efficiency and service life of the product, thus restricting the development of microelectronics integration technology. h-BN has high insulation and high thermal conductivity and is a thermally conductive filler with great potential.

Lubricant additives

h-BN has moderate hardness, higher than commonly used solid lubricants aluminum disulfide and graphite, but lower than diamond, and has better load-bearing capacity. h-BN spherical nanoparticles have good wear resistance, long service life, and have certain Chemically inert and stable, it has a series of excellent characteristics as a lubricant additive. Due to its high temperature stability and low friction coefficient, h-BN material, as a high temperature solid lubricant, has better high temperature resistance and load resistance than ordinary lubricants, and it still has high stability even under corrosive conditions. In addition, h-BN, as a non-toxic white material, has no pollution to the environment and may become a green lubricant additive.

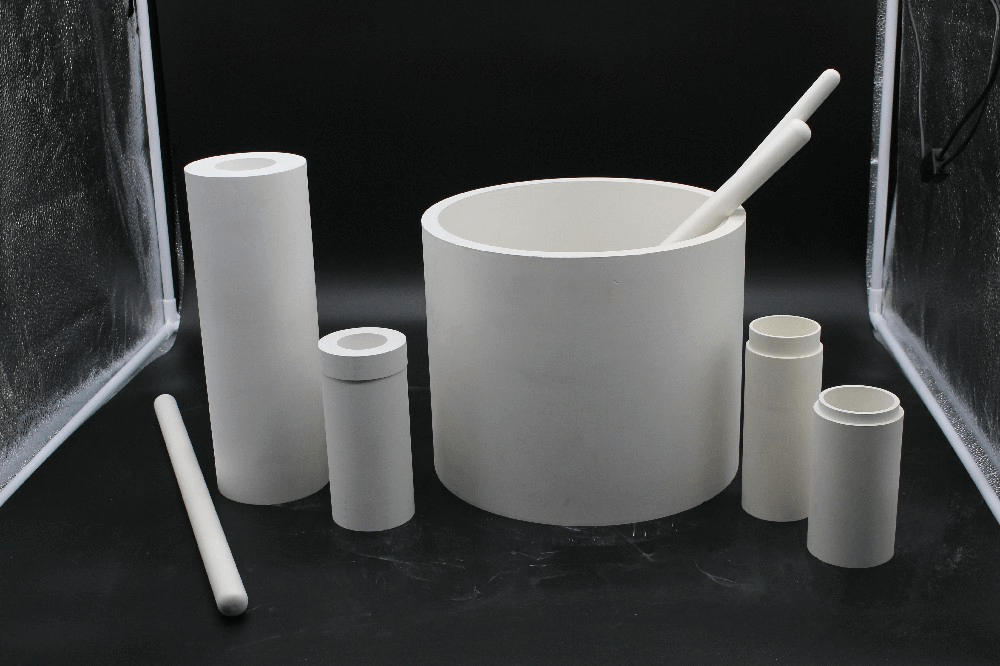

Ceramic material

h-BN ceramic material has advantages that cannot be ignored as a special ceramic material due to its extremely high thermal conductivity, extremely low thermal expansion coefficient, good electrical insulation properties, and non-wetting with most metals. h-BN fiber has the excellent properties of both fiber materials and h-BN ceramic materials, and can be used as a reinforcing agent for ceramics and composite materials.

Catalyst carrier

Traditional oxygen-containing catalyst carriers such as alumina, silica, and molecular sieves have great catalytic activity, but are unstable under high temperature conditions and have low thermal conductivity. Activated carbon has a very high specific surface area, good thermal stability, acid and alkali resistance, and easy adjustment of properties. It is widely used in industry and is often used as a catalyst carrier. However, activated carbon is extremely unstable in an aerobic environment and its mechanical strength is also very low. Compared with activated carbon, h-BN materials have great advantages in chemical properties, thermal stability and thermal conductivity. If they are successfully used as catalyst carriers, they can overcome many shortcomings of traditional catalysts.

Hydrogen storage

Hydrogen is currently the cleanest energy source and has good development prospects in solving air pollution problems. The safe and effective use and storage of hydrogen is currently the most urgent problem for researchers. Since h-BN nanotubes and hollow sphere h-BN have holes for adsorbing hydrogen atoms, they can be considered as good hydrogen storage materials.

Drug carrier materials

h-BN is resistant to high temperatures, has strong oxidation and corrosion resistance, stable chemical properties and strong neutron absorption capacity. Compared with carbon-based materials such as graphene, h-BN has better biocompatibility and has great potential in biomedical applications. It has great application value and can be used as a biological scaffold and a carrier material for drug delivery.

Adsorbent material

Porous h-BN has a unique structure and performance. Due to its high specific surface area, it has a strong adsorption effect on organic solvents such as hydrocarbons, heavy metal ions, and oils. It can protect the environment and save money in oil-water separation and sewage purification. The aspect of resources has great research value.

Anti-corrosive coating

With the continuous deepening of h-BN related research, its application in the field of metal corrosion protection is becoming more and more extensive. The applications of h-BN in the field of metal corrosion protection mainly include: metal surface pretreatment, pure h-BN deposition coating, and h-BN modified organic anti-corrosion coating. Anti-corrosive coatings represented by epoxy resin play an important role in metal corrosion protection, but there is still some room for improvement. The introduction of inorganic nanopowders can improve the barrier properties of the coating, enhance the density of the coating, extend the diffusion path of corrosive media and increase the service life of the coating. This is one of the important directions in current anti-corrosion coating research. Utilizing h-BN's layered structure, high chemical stability, strong insulation and other excellent properties, the performance of anti-corrosion coatings can be significantly improved.

The many excellent characteristics of h-BN make it popular for applications in solid lubrication, composite ceramics, aerospace and other fields. With the deepening of research and the continuous maturation of preparation methods, it is believed that the potential excellent properties and application prospects of h-BN will continue to grow. Continuing to be discovered, h-BN has the potential to be widely used in various fields of materials science and other related fields.