As the next generation of heating technology following alloy heating wires and PTC heating elements, HTCC is widely utilized in daily life, industrial and agricultural technology, telecommunications, medical care, environmental protection, and various other fields requiring low-to-medium temperature heating.

Dimensions: Customized

Resistance Range: 0.5-0.7Ω / 1.3-2.0Ω / 1.1-1.25Ω

Operating Voltage: 3.7V - 5V

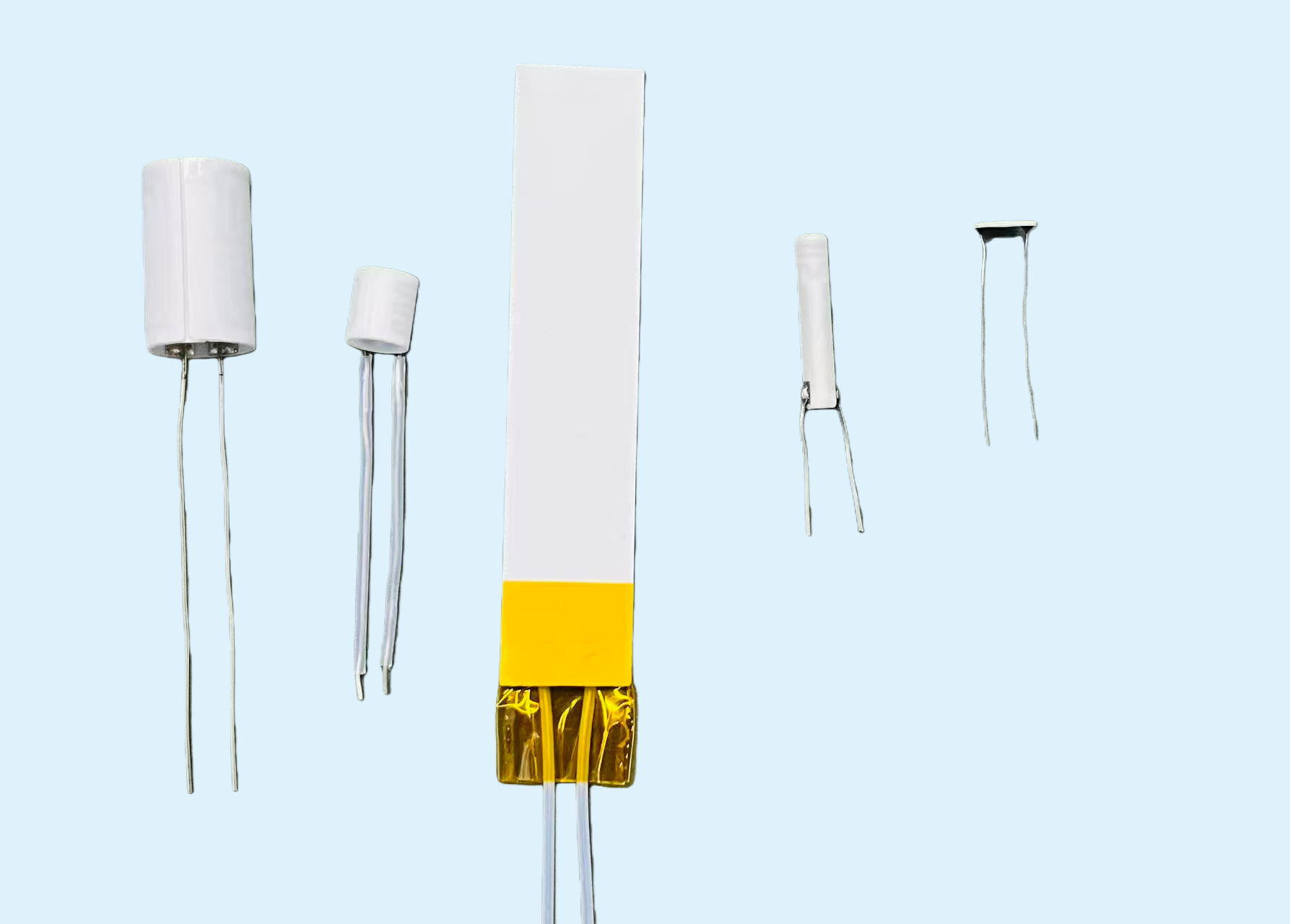

Shape: Ring / Annular

Material: HTCC (High-Temperature Co-fired Ceramic)

Application: HNB / Tobacco Paste Vaporization

Customization: Available upon request

Our ceramic heating elements are widely utilized across various sectors: in household appliances, they are used in small fan heaters, hair dryers, clothes dryers, space heaters, mobile cooling/heating units, desiccant dryers, electric splints, electric irons, soldering irons, hair straighteners, curling irons, electronic thermoses, warming cabinets, electric cookers, ceramic toilet heaters, and water heaters; in the industrial sector, they are applied to industrial drying equipment, electric bonding machines, and heaters for water, oil, and acid-base liquids; in the electronics industry, they serve as constant temperature baths for specialized small crystal devices; and in the medical field, they are integrated into infrared physical therapy equipment and intravenous (IV) fluid heaters.

Item |

Test Conditions |

Unit |

Performance |

|---|---|---|---|

| Color | -- | -- | White |

| Status | -- | -- | Dense |

| Substrate Material | -- | -- | ≥ 96% Alumina Ceramic |

| Density | GB/T 2413-1980 | g/cm³ | > 3.7 |

| Camber | -- | mm | < 0.2mm |

| Lead Wire Pull Strength | SJ/Z 9001.33-1987 | kg | Horizontal ≥ 5; Vertical ≥ 3 |

| Flexural Strength | GB/T 4741-1999 | MPa | > 300 |

| Thermal Conductivity | 25 ± 1°C | W/(m·K) | ≥ 20 |

| Dielectric Strength | 25 ± 1°C; 110V: 1800V/10s; 220V: 3700V/1s | -- | Leakage Current < 0.62 mA |

| Insulation Resistance | GB/T 10064-2006; DC500V | MΩ | > 100 |

| Resistance | 25 ± 1°C | Ω | Custom range ± 10% |

| Cycle Test | Rated voltage/temp; ≤ 280°C; 60 min ON / 60 min OFF | -- | 1,000 cycles without damage |

| Power-on Test | Rated voltage; 20 sec in air; Surface temp 600°C - 750°C | -- | No damage |

| High-Temp Endurance | Max temperature 500°C - 700°C; Continuous power-on | -- | > 24 hours |