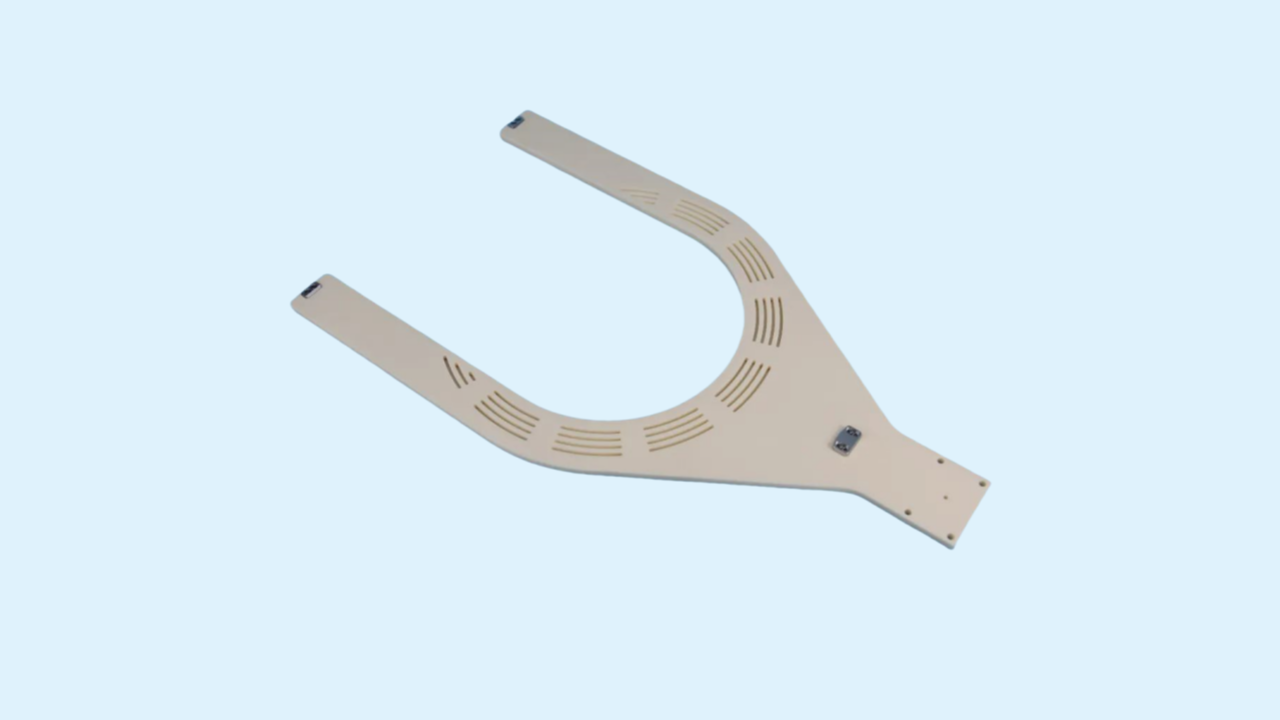

High Rigidity & Lightweight

Utilizes AX-01 Multiphasic Alumina to achieve a high Young's modulus (200-300 GPa) while maintaining low mass. This ensures minimal vibration and tip deflection during high-speed robotic acceleration.

Ultra-Precise Surface Flatness

The contact surface is precision-ground to achieve exceptional flatness (up to < 0.01mm). This prevents micro-scratching on the wafer backside and ensures a perfectly uniform interface.

Wear Resistance & Cleanliness

The dense AX-01 ceramic (density > 4.10 g/cm³) significantly reduces particle generation compared to traditional metal effectors. It is chemically inert and ideal for ISO Class 1 cleanroom standards.

Thermal & ESD Stability

Features controlled volume resistivity (< 2.0*10¹ Ω·cm) to dissipate static charges. Its low thermal expansion (8.07 at RT~400°C) ensures dimensional stability during heat-intensive processes.