In the industrial world, equipment downtime is the biggest cost killer. Alumina Ceramic exists to solve this problem. As an engineering material that strikes a perfect balance between hardness, heat resistance, and insulation, it can extend the lifespan of your mechanical parts by 5 to 10 times under extreme conditions.

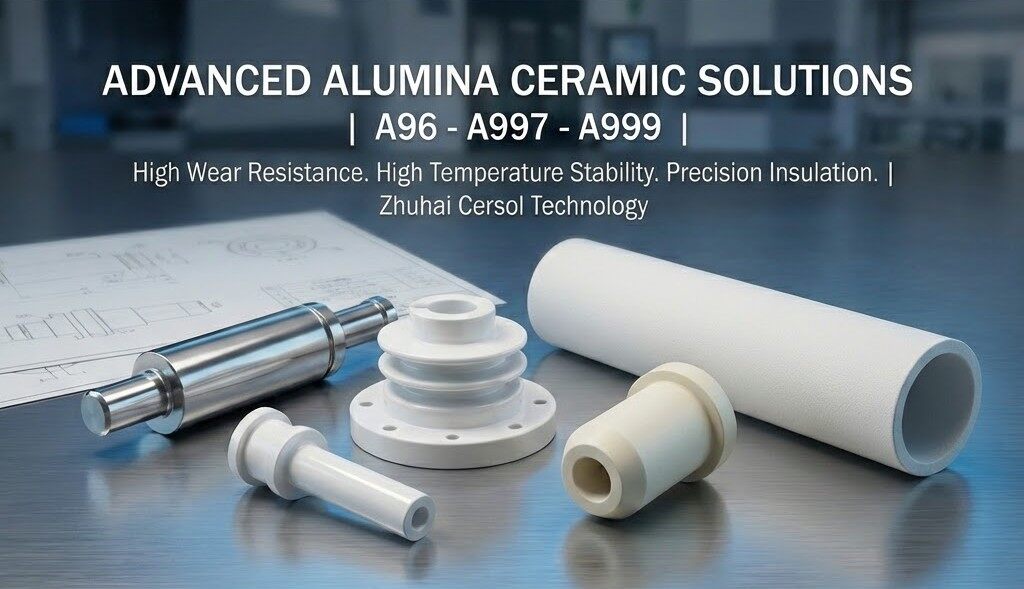

Whether you need a seal ring resistant to slurry abrasion or an electronic substrate that remains insulating at high temperatures, Zhuhai Cersol Technology provides customized Alumina solutions (A96 - A999)

Alumina (Al2O3) is the "versatile workhorse" of industrial ceramics. It is not fragile porcelain but a dense inorganic non-metallic material formed through high-temperature sintering.

Appearance: Depending on purity, it appears White (A96/A999) or Off-white (A997)

Key Characteristic: It offers zero water absorption (0%) across all our grades, ensuring stability in wet environments

Selection should be based on facts, not guesses. The following data comes from our internal laboratory tests

|

Property |

Unit |

A96 |

A997 |

A999 |

|---|---|---|---|---|

|

Color |

- |

White |

Off-white |

White |

|

Density |

g/cm³ |

> 3.86 |

> 3.90 |

> 3.95 |

|

Water Absorption |

% |

0 |

0 |

0 |

|

Grain Size (Average) |

μm |

5 - 8 |

4.47 |

5.87 |

|

Vickers Hardness |

GPa |

15 |

16 |

16.5 |

|

Flexural Strength |

MPa |

> 350 |

> 350 |

> 450 |

|

Young's Modulus |

GPa |

340 |

380 |

380 |

|

Poisson's Ratio |

- |

0.23 |

0.23 |

0.23 |

|

Thermal Conductivity |

W/(m·K) |

26 |

32 |

34 |

|

Thermal Shock (ΔT) |

°C |

200 |

200 |

250 |

|

Thermal Expansion Coeff. |

10⁻⁶/°C |

7 |

7.2 |

7.5 |

|

Specific Heat Capacity |

J/(g·K) |

0.7 |

0.77 |

0.78 |

|

Dielectric Breakdown |

KV/mm |

14 |

15 |

15 |

|

Volume Resistivity |

Ω·cm |

> 1014 |

> 1014 |

> 1015 |

|

Dielectric Constant (1MHz) |

- |

9.4 |

9.7 |

9.9 |

|

Dielectric Loss (1MHz) |

×10⁻⁴ |

40 |

10.9 |

2.2 |

Source: Cersol Technical Data Sheet

Why is it the standard for wear resistance?

Hardness Beyond Steel: Even our entry-level A96 achieves a Vickers Hardness of 15 GPa

High Strength Support: The A999 series offers a flexural strength greater than 450 MPa

In environments where plastics melt and metals soften, Alumina Ceramic stands firm.

Heat Dissipation:A999 features a thermal conductivity of 34 W/(m*K)

Thermal Shock Resistance: While ceramics generally fear rapid temperature changes, our A999 can withstand a thermal shock of 250°C

For manufacturers of high-voltage equipment, insulation reliability is a matter of safety.

Dielectric Strength: Our ceramics offer a breakdown voltage of 14 - 15 KV/mm

Volume Resistivity: With volume resistivity exceeding 1014Ohm*cm (and up to 1015 for A999)

The Issue: Unlike metals, Alumina ceramic does not deform plastically under stress; it cracks. It has low resistance to impact loads. If your application involves heavy hammering or dropping, Alumina might shatter.

The Solution: Use Zirconia (ZrO2) for high-impact areas, or design your Alumina parts with chamfered edges to reduce stress concentration.

The Issue: While Alumina withstands high temperatures (up to 1700°C), it dislikes sudden temperature changes. A rapid change of more than 200°C-250°C (Thermal Shock) can cause thermal fractures.

The Solution: If you need to quench parts from red-hot to cold water instantly, Silicon Nitride (Si3N4) is a better choice.

The Issue: Because it is harder than tungsten carbide, Alumina cannot be machined with standard HSS or carbide tools after sintering. It requires expensive diamond tooling, making complex modifications costly.

The Solution: Consult with Cersol engineers before sintering. We can perform "Green Machining" (shaping before firing) to significantly reduce costs.

Choose A96: The Cost-Effective Choice. Ideal for general wear liners or pump seals. It offers excellent hardness (15 GPa) at a competitive price

Choose A997: Standard Precision. With a specific average grain size of 4.47 um

Choose A999: Extreme Performance. It features the highest density (>3.95 g/cm3) and strength, designed for semiconductor equipment or vacuum environments where impurities must be minimized

Q: Does your ceramic absorb liquid?

A: No. The water absorption rate for all our grades (A96/A997/A999) is 0%

. This ensures dimensional stability in chemical or wet environments.

Q: How tough is the material?

A: Alumina is very hard but rigid. Its Young's Modulus is between 340 and 380 GPa

. While it resists wear exceptionally well, it should be installed carefully to avoid impact shocks.

We are not just a supplier; we are your material consultants. We ensure every batch meets strict physical standards.

Contact Us: For specific technical inquiries or a quote.

Web:

Email: info@ceramic-solutions.com

Phone: +86 13536586031