RSiC: Recrystallized Silicon Carbide

Max. application temperature: 1650℃.

Features: great

material properties, high strength, good wearing and corrosion

resistance, excellent thermal shock resistance and thermal conductivity.

Applications: tableware industry, high temperature structural ceramics and other high temperature industries.

RSiC products are made by casting special treated high-purity SiC material and sintered in vacuum high temperature furnace.

Technical Indexes

Item

Index

Max.working temprature

Oxidising atmosphere(℃)

1650

Inert atmosphere(℃)

2300

Bending strength

@20℃(MPa)

80-100

@1100℃(MPa)

100-120

Porosity(%)

15

Bulk density @20℃(g/cm3)

2.65-2.73

Young's modulus @20℃(GPa)

280

Thermal cnductivity @1200℃(W/MK)

26

Thermal expansion @20-1000℃(10-6K-1)

4.8

PH resistance

1-14

Material Properties

High strength, good wearing and corrosion resistance, excellent thermal shock resistance and thermal conductivity. Max. application temperature is 1650℃.

Application

Widely used in tableware industry, high temperature structural ceramics and other high temperature industries.

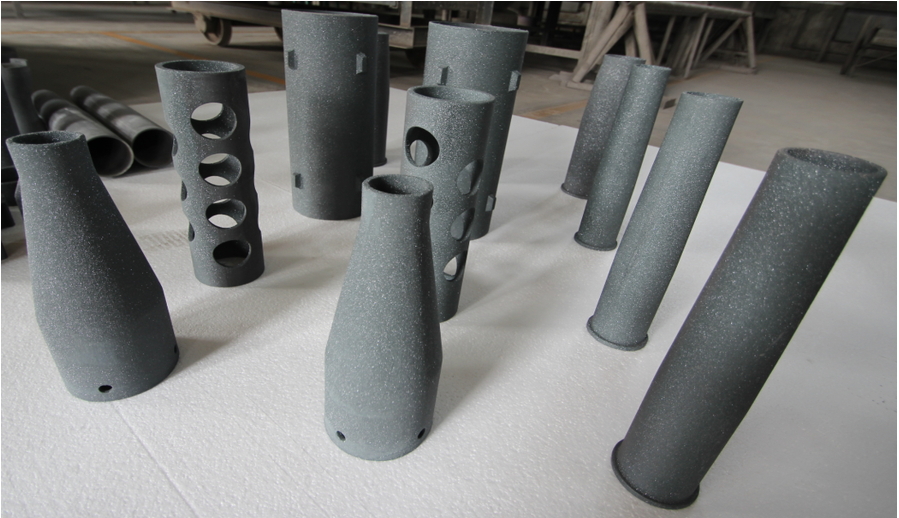

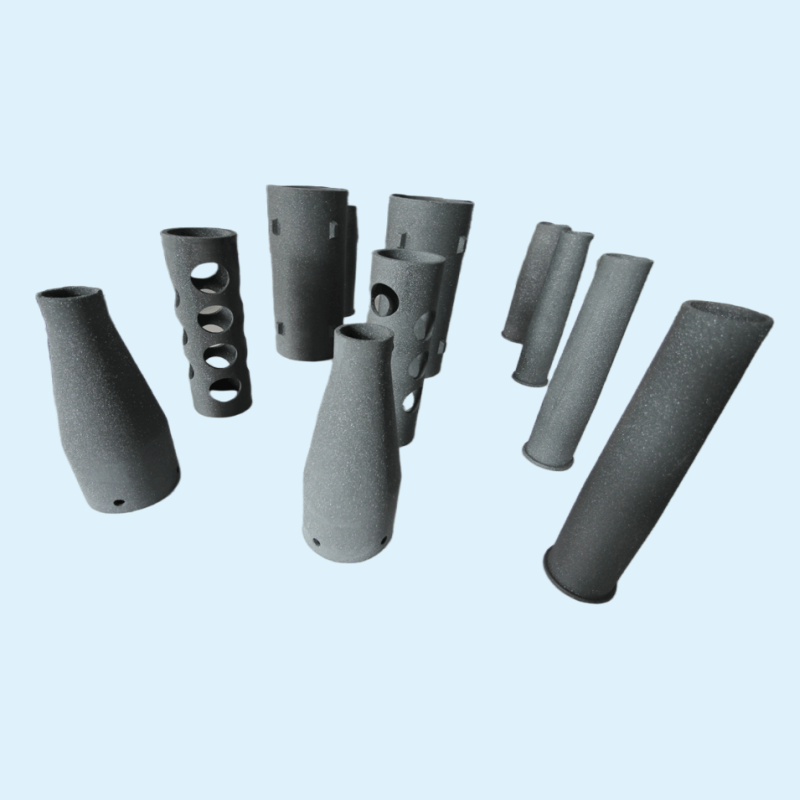

We have different types of Recrystallized Silicon Carbide Products, RSiC Beams, RSiC Batts, RSiC Rollers And Pipes, RSiC Burner Nozzles and Special Parts.

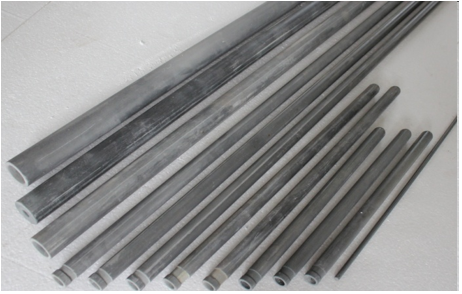

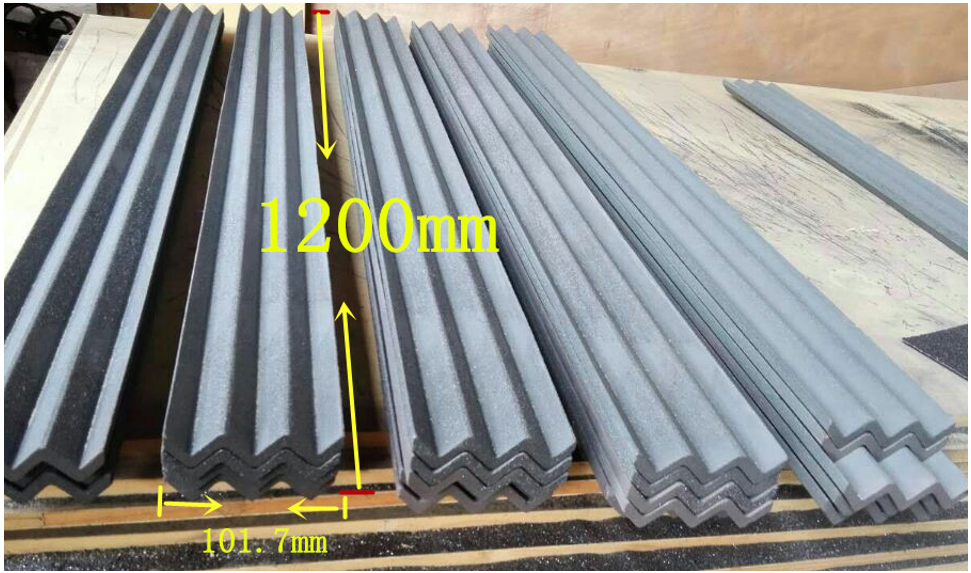

RSiC Beams: Mainly used in high temperature alumina roller and structural ceramics industries.

RSiC Batts: Mainly used in high temperature alumina industry and fast sintering tableware industry.