The working principle mainly includes the following aspects:

Grading process: The grading wheel rotates at high speed in the grading

housing (the speed can be adjusted), forming a strong centrifugal

force. When the air-powder mixture enters the interior of the

classifying wheel, due to the centrifugal force, large or heavy

particles will be thrown to the periphery of the classifying wheel, and

finally fall into the crushing host to continue crushing; while small or

light materials will be thrown to the periphery of the classifying

wheel due to centrifugal force. Smaller and hovering inside the grading wheel, it is

then guided to a high place by the induced draft fan and moved through

the pipe to the next component for grading or collection.

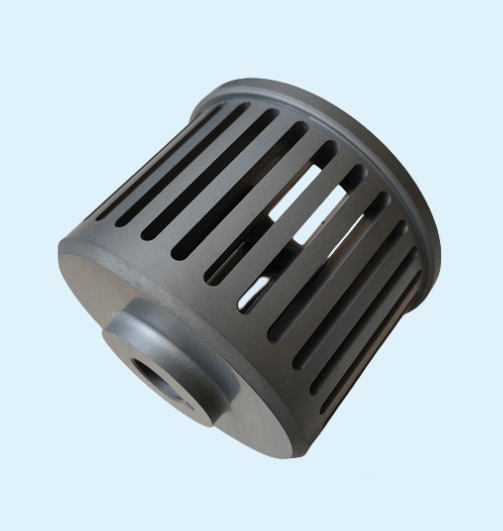

Classification effect: The design of the classification wheel allows the particles to be further refined while being

impacted and rubbed so that they can be better taken away by the

airflow. Small holes of specific sizes inside the grading chamber can be

adjusted as needed to achieve grading of different finenesses.

Classification mechanism: The blades on the classification wheel will

hit and rub the particles, making them smaller and easier to be carried

by the airflow. The speed of the classifying wheel can be adjusted by

frequency conversion to adjust the size of the centrifugal force to

achieve the purpose of separating materials of specified particle size.

To sum up, the principle of the airflow mill classification wheel is to

achieve the classification and refinement of particles through the

centrifugal force generated by high-speed rotation, combined with the

impact and friction of the blades on the classification wheel on the

particles, and the induced wind force of the induced draft fan.

Tell us your needs, we have a Technical Consultant to provide you with Ceramic Solutions, click to consult!