Applications

Nano sand mill, conveying equipment, conveying pipeline, etc

Features

● High wear resistance

● High corrosion resistance

● High oxidation resistance

● Thermal shock resistance

● Long life

● High thermal conductivity, good thermal conductivity

● Strength does not change in high temperature environment

● Fast molding, high yield, no pollution

● Small density, light weight

Precision machining

1. High-pure silicon powder

2. Democratic processing: dry forming, waiting for static pressure molding, grouting molding.

3.

Machining: graphic grinding, outer diameter / internal diameter

grinding, refined carving machine processing, grinding, polishing

grinding.

Silicon Carbide Material Report

| Silicon Carbide Material Report | Purity | 99% |

| Color | black | |

| Desity(g/cm3) | 3.16 | |

| Water absorption | 0 | |

| Modules of Elasity(GPa) | 450 | |

| Compressive Strength(MPa) | 224 | |

| Flexural strength(MPa) | 400 | |

| Poisson's ratio | 0.14 | |

| Vickers Hardness(MPa) | 30 | |

| Maximum use Temprature(℃) | 1600 | |

|

Thermal Expansion Coefficient (1/℃x 10-6)-RT 500℃ |

3.9 | |

|

Thermal Expansion Coefficient (1/℃x 10-6)-RT 800℃ |

4.3 | |

| Thermal Conductivity(W/m·k) | 40 | |

| Thermal Shock Resistance(Δt ℃) | 300 | |

| Volume resistivity(25℃) | 3X106 | |

| Dielectric Constant | 10GHz |

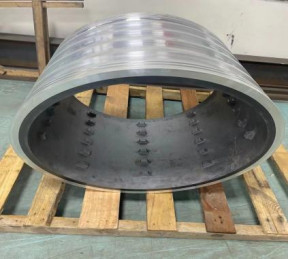

The

silicon carbide wear-resistant barrel body is factory for strict size

and surface fluorescence penetration testing. The density of silicon

carbide wear-resistant barrel is greater than 3.14g/cm3, and the Vickers

hardness is above 23GPa, which is highly wear-resistant. The silicon

carbide wear-resistant barrel material has passed TUVFDA certification,

which can meet the requirements of food-grade media transportation.

Tell us your needs, we have a Technical Consultant to provide you with Ceramic Solutions, click to consult!